SIZING AND SELECTION DRIVE SHAFT COUPLINGS

Symbols

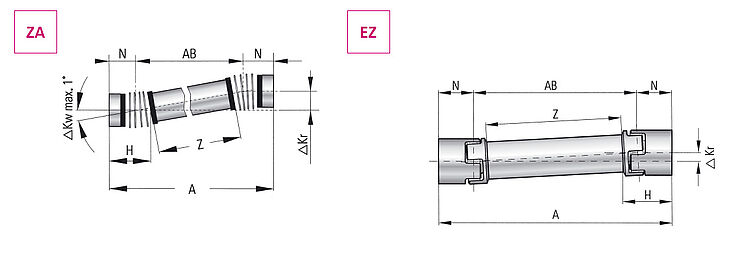

| A | Overall length (mm) |

| AB | Distance between flextures (mm) AB = (A – 2xN) |

| Z | Tube length (mm) Z = (A – 2xH) |

| H | Length of coupling ends (mm) |

| N | Length to flexture (mm) |

| TAS | Peak torque of the drive (Nm) |

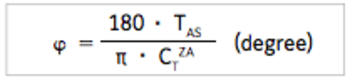

| φ | Torsional deflection (degree) |

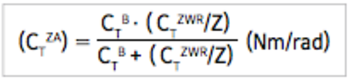

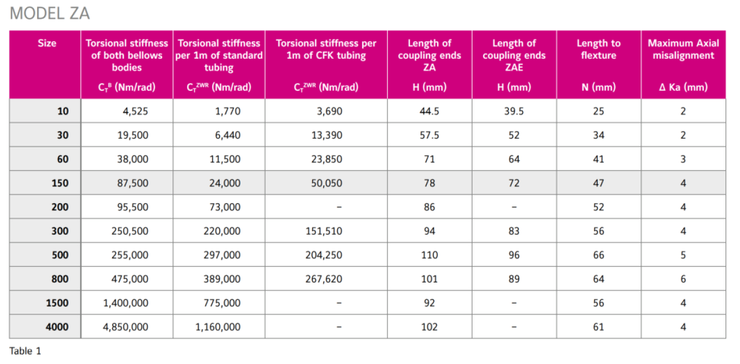

| CTB | Torsional stiffness of both flexible elements (Nm/rad) |

| CTZWR | Torsional stiffness per 1m of tubing (Nm/rad) |

| CTZA | Total torsional stiffness (Nm/rad) |

| nk | Critical speed (1/min.) |

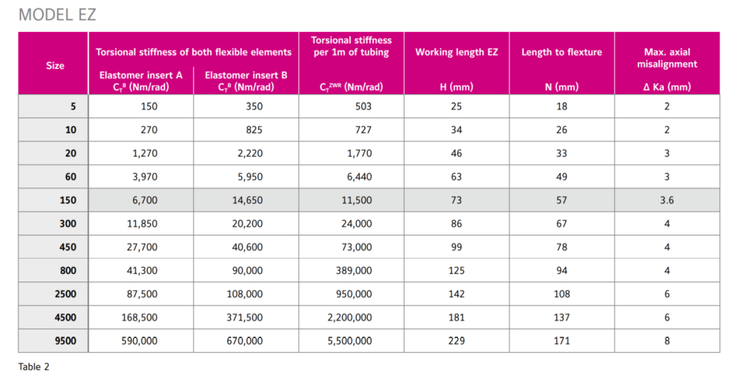

| CTdynE | Dynamic torsional stiffness of both elastomer inserts (Nm/rad) |

| CTdynEZ | Total torsional stiffness (Nm/rad) |

According to torsional deflection

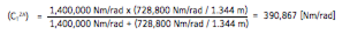

Condition: Line shaft ZA, size 1.500 TAS = 1.500 Nm

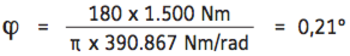

Wanted: Torsional deflection at maximum acceleration torque TAS

Measurement (A) of the line shaft = 1,5 m

Length (Z) of tubing = A - (2xH) = 1,344 m

With a maximum torque of 1.500 Nm the torsional deflection is 0,21°.

R+W Calculation Program

Using proprietary software, R+W will calculate the specific mechanical details of exactly the model you plan to use. Overall length, tube materials (e.g. steel, aluminum, CFK), and other factors are used to determine a number of performance values unique to your line shaft coupling.

| Critical Speed | nk | 1/min. |

| Torsional stiffness of tubing | CTZWR | Nm/rad |

| Overall stiffness | CTZA | Nm/rad |

| Torsional deflection | φ | Grad-Min-Sec |

| Total weight | m | kg |

| Moment of inertia | J | kgm2 |

| Maximum misalignment | ΔKr | mm |