PRÄZISIONSKUPPLUNGEN

FOR USE IN HAZARDOUS AREAS

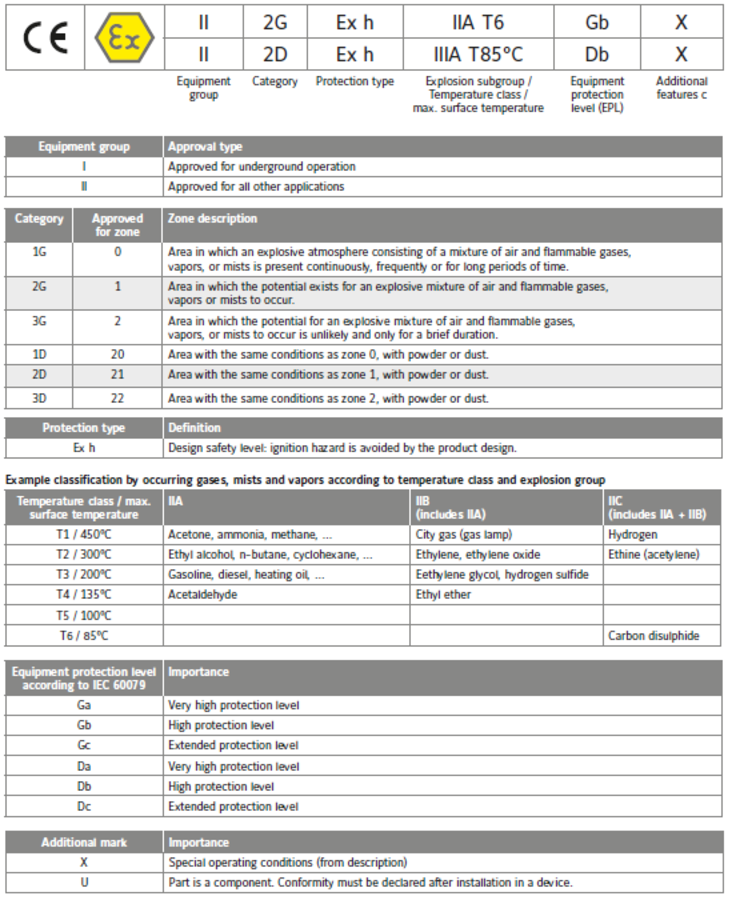

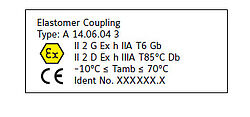

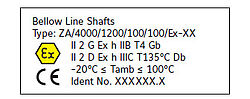

Marking example

Based on the ATEX markings the product can be certified for suitability under certain conditions.

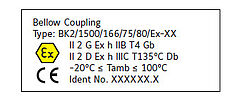

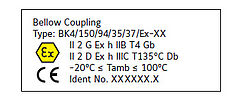

ATEX metal Bellows Couplings

- CONSTRUCTION

Dimensions and materials of the standard models remain largely intact. - PERFORMANCE RATINGS

- The rated torque of the standard models must be reduced by 30 %.

- OPERATION

- According to the Machinery Directive, ATEX metal bellow couplings must only be operated inside a sealed housing.

- Both the input and output shafts must be monitored to guarantee shut down in the case of coupling failure.

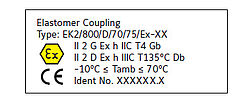

ATEX Elastomer Couplings

- CONSTRUCTION

Dimensions and materials of the standard models remain largely intact. - PERFORMANCE RATINGS

All permitted misalignment, speed, and torque ratings of the standard models. - OPERATION

- According to the Machinery Directive, ATEX elastomer couplings must only be operated inside a sealed housing.

- Both the input and output shafts must be monitored to guarantee shut down in the case of coupling failure.

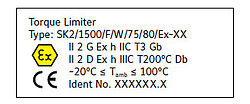

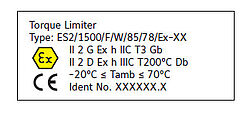

ATEX torque Couplings

- CONSTRUCTION

Dimensions and materials of the standard models remain largely intact.- Generally full disengagement style torque limiters are used in ATEX environments in order to avoid high temperatures from excess friction after disengagement.

- For ES2 torque limiters the inserts come in version “D” (Sh65D) which is electrically conductive to provide continuity for any potential electrostatic charges.

- PERFORMANCE RATINGS

All permitted misalignments, speed and torque ratings of the standard models. - OPERATION

- ATEX safety couplings must be used with an ATEX proximity switch. The emergency stop function in conjunction with activation of the switch must be fully tested for proper function prior to commissioning of the machine.

- When bellow couplings are incorporated they must only be operated inside a sealed housing. Both the input and output shafts must be monitored to guarantee sut down in the case of bellows failure.

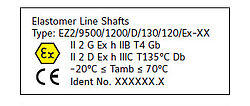

ATEX Line Shafts

- CONSTRUCTION

- Dimensions and materials of the standard models remain largely intact.

- For EZ type line shafts the inserts come in version “D” (Sh65D) which is electrically conductive to provide continuity for any potential electrostatic charges.

- PERFORMANCE RATINGS

For EZ2 type line shafts all permitted misalignments, speed and torque ratings of the standard models. For ZA and ZAE type line shafts the rated torque must be reduced by 30 %. The allowable operating speed depends on the overall length of the line shaft and is available upon request. - OPERATION

When bellow couplings are incorporated they must only be operated inside a sealed housing. Both the input and output shafts must be monitored to guarantee shut down in the case of bellow failure.

GENERAL INFORMATION PRECISION COUPLINGS

GENERAL INFORMATION PRECISION COUPLINGS

Prior to deviating from any of the previous safety instructions please contact R+W.

The use of devices and components in potentially explosive atmospheres areas is governed by the European directives 2014/34/EU (ATEX). According to this they are with CE and receive an EU declaration of conformity as a device. The presented products are non-electrical equipment of category 2.

According to directive 2014/34/EU each delivery of an ATEX coupling requires the inclusion of special installation and operating manuals and the EU declaration of conformity issued by the manufacturer. All necessary values and specifications for installation and operation can be found in these documents.

accordance with the Machinery Directive 2006/42/EC and the guideline for the application of the Machinery Directive 2006/42/EC of the European Commission For Enterprise and Industry, 2nd edition June 2010, editor Ian Fraser, R+W couplings are components and therefore not a machine or an incomplete machine. As a component within the meaning of the Machinery Directive, R+W couplings are not to be marked with a CE marking, receive neither CE declaration of conformity nor installation and no serial number, and is therefore not covered by the Machinery Directive.

All statements made about ATEX conforming products are based on our present knowledge and experience. R+W reserves the right to change technical specifications.

GENERAL INFORMATION INDUSTRIAL COUPLINGS

- The use of devices and components in potentially explosive atmospheres areas is governed by the European directives 2014/34/EU (ATEX). According to this they are with CE and receive an EU declaration of conformity as a device. The presented products are non-electrical equipment of category 2.

- According to directive 2014/34/EU each delivery of an ATEX coupling requires the inclusion of special installation and operating manuals and the EU declaration of conformity issued by the manufacturer. All necessary values and specifications for installation and operation can be found in these documents.

- In accordance with the Machinery Directive 2006/42/EC and the guideline for the application of the Machinery Directive 2006/42/EC of the European Commission For Enterprise and Industry, 2nd edition June 2010, editor Ian Fraser, R+W couplings are components and therefore not a machine or an incomplete machine. As a component within the meaning of the Machinery Directive, R+W couplings are not to be marked with a CE marking, receive neither CE declaration of conformity nor installation and no serial number, and is therefore not covered by the Machinery Directive.

- All models of BX, LP, EK and ST are available with ATEX certification on request. The Model BZ coupling is not intended for use in potentially explosive atmospheres.

- All R+W ATEX couplings are designed for use in general suitable for industry (device group II). The operation is in the explosion endangered zones 1 and 2 (category 2G) and 21 and 22 (category 2D).

- Product specific information about ATEX certified couplings, such as temperature class, are available on request.

- All statements made about ATEX conforming products are based on our present knowledge and experience. R+W reserves the right to change technical specifications.